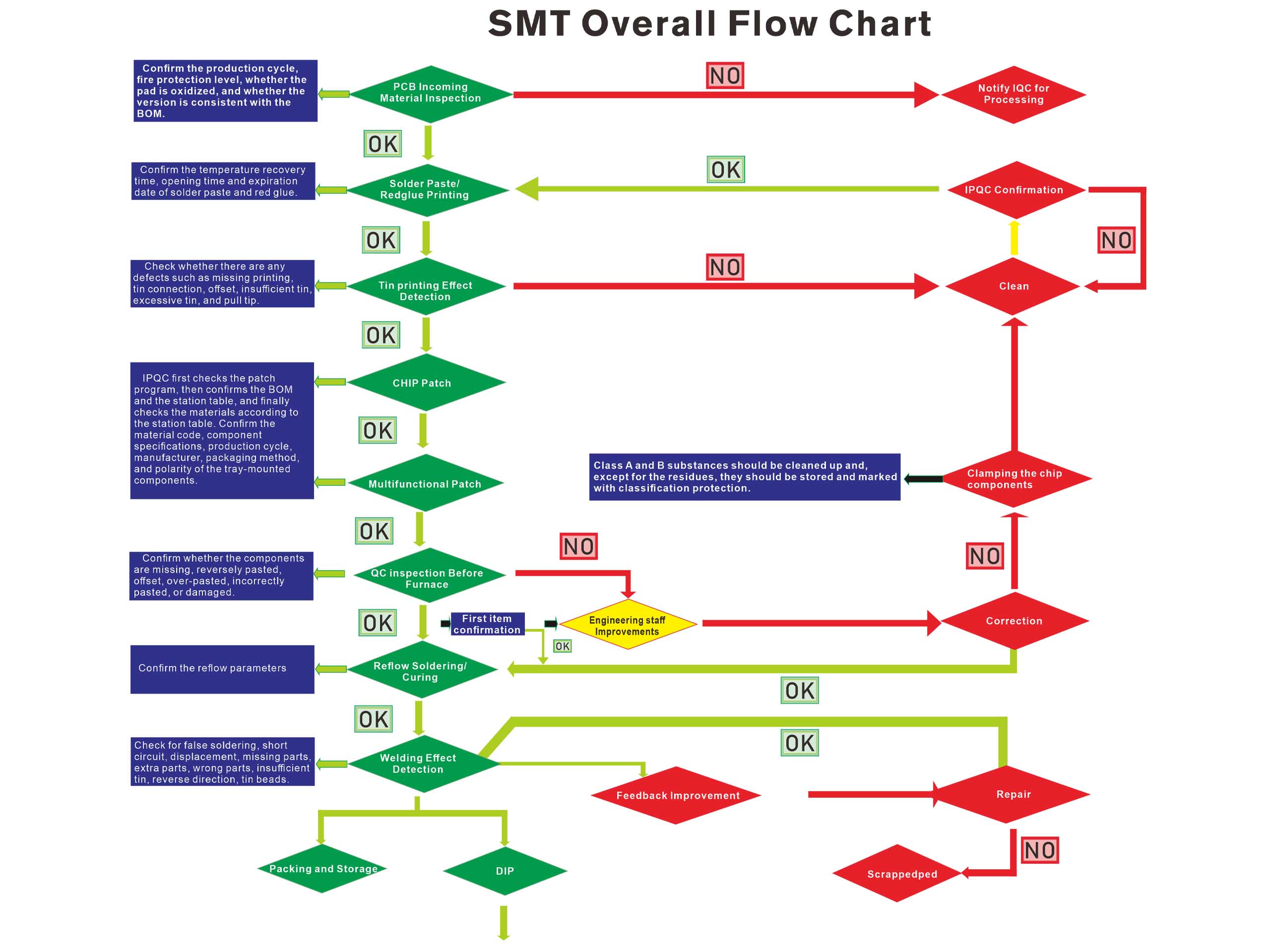

Oku kulandelayo yinkqubo epheleleyo yokuvelisa ukusuka kwi-SMT (i-teknoloji ye-surface mount) ukuya kwi-DIP (i-double in-line package), kwi-AI yokubona kunye ne-ASSY (indibano), kunye nabasebenzi bezobugcisa ababonelela ngesikhokelo kuyo yonke inkqubo. Le nkqubo iquka amakhonkco angundoqo kwimveliso yombane ukuqinisekisa umgangatho ophezulu kunye nemveliso esebenzayo.

Gqibezela inkqubo yokwenziwa kweSMT→DIP→uhlolo lweAI→ASSY

1. SMT (iteknoloji yokunyuswa komphezulu)

I-SMT yinkqubo engundoqo yokwenziwa kombane, esetyenziswa ikakhulu ukufakela izixhobo zokuxhoma phezulu (SMD) kwi-PCB.

(1) Ushicilelo lwe-solder paste

Isixhobo: umshicileli we-solder paste.

Amanyathelo:

Lungisa i-PCB kwi-workbench yomshicileli.

Shicilela intlama ye-solder ngokuchanekileyo kwiiphedi ze-PCB ngokusebenzisa i-mesh yentsimbi.

Qwalasela umgangatho woshicilelo lwe-solder paste ukuqinisekisa ukuba akukho offset, ushicilelo olulahlekileyo okanye ushicilelo olugqithisileyo.

Amanqaku aphambili:

I-viscosity kunye nobukhulu be-solder paste kufuneka ihlangabezane neemfuno.

Umnatha wentsimbi kufuneka ucocwe rhoqo ukuze ugweme ukuvala.

(2) Ukubekwa kwecandelo

Izixhobo: Khetha kwaye ubeke umatshini.

Amanyathelo:

Layisha amacandelo e-SMD kwi-feeder yomatshini we-SMD.

Umatshini we-SMD uchola amacandelo ngombhobho kwaye uwabeke ngokuchanekileyo kwindawo echaziweyo yePCB ngokwenkqubo.

Jonga ukuchaneka kokubekwa ukuze uqiniseke ukuba akukho offset, iindawo ezingalunganga okanye iindawo ezingekhoyo.

Amanqaku aphambili:

I-polarity kunye nolwalathiso lwamacandelo kufuneka luchaneke.

Umbhobho womatshini we-SMD kufuneka ugcinwe rhoqo ukuze ugweme umonakalo kumacandelo.

(3) I-reflow soldering

Izixhobo: Iziko lokuntywila ngokutsha.

Amanyathelo:

Thumela iPCB enyusiweyo kwireflow soldering eziko.

Emva kwezigaba ezine zokufudumeza, ukushisa okuqhubekayo, ukuphindaphinda kunye nokupholisa, i-solder paste iyancibilika kwaye i-joint solder ethembekileyo yenziwe.

Jonga umgangatho we-soldering ukuqinisekisa ukuba akukho ziphene ezifana neendawo ezibandayo ze-solder, i-bridging okanye i-tombstones.

Amanqaku aphambili:

Ijika lobushushu le-reflow soldering kufuneka liphuculwe ngokweempawu ze-solder paste kunye namacandelo.

Ukulinganisa ubushushu beziko rhoqo ukuqinisekisa umgangatho ozinzileyo we-welding.

(4) Uhlolo lwe-AOI (uhlolo oluzenzekelayo lwamehlo)

Izixhobo: isixhobo sokuhlola esizenzekelayo (AOI).

Amanyathelo:

Optically scan i-PCB ethengisiweyo ukubona umgangatho wamalungu e-solder kunye nokuchaneka kwecandelo.

Rekhoda kwaye uhlalutye iziphene kunye nengxelo kwinkqubo yangaphambili yokulungiswa.

Amanqaku aphambili:

Inkqubo ye-AOI kufuneka iphuculwe ngokoyilo lwePCB.

Lungiselela izixhobo rhoqo ukuqinisekisa ukuchaneka kokufunyanwa.

2. Inkqubo ye-DIP (i-dual in-line package).

Inkqubo ye-DIP isetyenziswa ikakhulu ukufaka i- through-hole components (THT) kwaye idla ngokusetyenziswa ngokudityaniswa nenkqubo ye-SMT.

(1) Ufakelo

Izixhobo: umatshini wokufaka ngesandla okanye ozenzekelayo.

Amanyathelo:

Faka icandelo lokutyhubela umngxuma kwindawo echaziweyo yePCB.

Jonga ukuchaneka kunye nokuzinza kokufakwa kwecandelo.

Amanqaku aphambili:

Izikhonkwane zecandelo kufuneka zinqunywe ubude obufanelekileyo.

Qinisekisa ukuba i-polarity yecandelo ichanekile.

(2) Ukuthengiswa kwamaza

Izixhobo: isithando somlilo esinamaza.

Amanyathelo:

Beka i-plug-in PCB kwi-wave soldering oven.

Ukuthengisa izikhonkwane zecandelo kwiipadi zePCB ngokuthengiswa kwamaza.

Jonga umgangatho we-solder ukuqinisekisa ukuba akukho ndawo zibandayo zesolder, ibhulorho okanye iindawo ezivuzayo zesolder.

Amanqaku aphambili:

Ubushushu kunye nesantya sokuthengiswa kwamaza kufuneka kuphuculwe ngokweempawu zePCB kunye namacandelo.

Coca i-solder bath rhoqo ukuze uthintele ukungcola okuchaphazela umgangatho we-solder.

(3) I-soldering manual

Lungisa ngesandla iPCB emva kokutywinwa kwamaza ukulungisa iziphene (ezinje ngokubanda kwamalungu kunye nokubopha ibhulorho).

Sebenzisa intsimbi yokugoqa okanye umpu womoya oshushu kwi-solder yendawo.

3. Ubhaqo lwe-AI (ukubona ubukrelekrele bokwenziwa)

Ukufunyanwa kwe-AI kusetyenziselwa ukuphucula ukusebenza kakuhle kunye nokuchaneka kokuchongwa komgangatho.

(1) Ukubonwa okubonakalayo kwe-AI

Izixhobo: I-AI yokubona inkqubo yokubona.

Amanyathelo:

Thatha imifanekiso enenkcazo ephezulu yePCB.

Hlalutya umfanekiso ngokusebenzisa i-algorithms ye-AI ukuchonga iziphene ze-soldering, i-component offset kunye nezinye iingxaki.

Yenza ingxelo yovavanyo kwaye uyondle emva kwenkqubo yemveliso.

Amanqaku aphambili:

Imodeli ye-AI kufuneka iqeqeshwe kwaye iphuculwe ngokusekelwe kwidatha yemveliso yangempela.

Hlaziya i-algorithm ye-AI rhoqo ukuphucula ukuchaneka kokubona.

(2) Uvavanyo olusebenzayo

Izixhobo: Izixhobo zovavanyo oluzenzekelayo (ATE).

Amanyathelo:

Yenza iimvavanyo zokusebenza zombane kwi-PCB ukuqinisekisa imisebenzi eqhelekileyo.

Rekhoda iziphumo zovavanyo kwaye uhlalutye izizathu zeemveliso ezineziphene.

Amanqaku aphambili:

Inkqubo yovavanyo kufuneka iyilwe ngokweempawu zemveliso.

Lungiselela rhoqo izixhobo zovavanyo ukuqinisekisa ukuchaneka kovavanyo.

4. Inkqubo ye-ASSY

I-ASSY yinkqubo yokudibanisa i-PCB kunye namanye amacandelo kwimveliso epheleleyo.

(1) Indibano yoomatshini

Amanyathelo:

Faka iPCB kwindlu okanye isibiyeli.

Qhagamshela amanye amacandelo afana neentambo, amaqhosha, kunye nezikrini zokubonisa.

Amanqaku aphambili:

Qinisekisa ukuchaneka kwendibano ukunqanda umonakalo kwi-PCB okanye amanye amalungu.

Sebenzisa izixhobo ezichasene ne-static ukukhusela umonakalo omileyo.

(2) Ukutshiswa kwesoftware

Amanyathelo:

Tshisa i-firmware okanye isoftwe kwinkumbulo yePCB.

Jonga iziphumo ezivuthayo ukuze uqinisekise ukuba isoftware isebenza ngokuqhelekileyo.

Amanqaku aphambili:

Inkqubo evuthayo kufuneka ihambelane nenguqulo ye-hardware.

Qinisekisa ukuba indawo etshisayo izinzile ukuphepha ukuphazamiseka.

(3) Uvavanyo lomatshini wonke

Amanyathelo:

Yenza iimvavanyo ezisebenzayo kwiimveliso ezidibeneyo.

Jonga imbonakalo, ukusebenza kunye nokuthembeka.

Amanqaku aphambili:

Izinto zovavanyo mazibandakanye yonke imisebenzi.

Ukurekhoda idatha yovavanyo kwaye uvelise iingxelo ezisemgangathweni.

(4) Ukupakishwa kunye nokuthunyelwa

Amanyathelo:

Ukupakishwa kwe-Anti-static yeemveliso ezifanelekileyo.

Ileyibhile, pakisha kwaye ulungiselele ukuthunyelwa.

Amanqaku aphambili:

Ukupakishwa kufuneka kuhlangabezane neemfuno zokuhamba kunye nokugcinwa.

Rekhoda ulwazi lokuthumela ngenqanawa ukuze kube lula ukulandela umkhondo.

5. Amanqaku aphambili

Ulawulo lokusingqongileyo:

Thintela umbane ongatshintshiyo kwaye usebenzise izixhobo ezichasene ne-static kunye nezixhobo.

Ukugcinwa kwezixhobo:

Rhoqo gcina kwaye ulungelelanise izixhobo ezinje ngabashicileli, oomatshini bokubeka, ii-oveni zokuqukumbela, ii-oveni ezithengiswayo zamaza, njl.

Uphuculo lwenkqubo:

Lungiselela iiparamitha zenkqubo ngokweemeko zokwenyani zemveliso.

Ulawulo lwemeko:

Inkqubo nganye kufuneka ihlole umgangatho ongqongqo ukuqinisekisa isivuno.